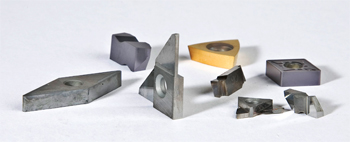

Carbide Inserts

New Inserts

Performance Carbide manufactures standard (turning, milling, threading, grooving, top-notch, dog bones, cut-off, spade drills) and special (to print, special widths, special radius) inserts.Our top quality inserts can be manufactured of:

- Carbide

- Cermets

- Ceramic

- CBN

- PCD

- HSS

- Silicon Nitride

Your inserts will be ground to industry standards or ground to your print.

OEM Insert Manufacturing Capabilities

Performance Carbide prides itself on its customer-focused approach to full-line indexable insert needs. Let us show you why we have been chosen by other manufacturers to fulfill their OEM needs. We can work with you to engineer special inserts or supply you with standard inserts to fulfill your cutting insert needs.

Our exacting work includes:

- Quality carbide from well-known industry-leading U.S. manufacturers

- Limitless grade and style selection

- Custom grinding to your specifications with the potential for altering the process to give you the optimum tool for your application

- Standard and special edge prep to enhance tool life of your insert

- Wide range of options for coatings available

Downsizing Inserts

Your dull inserts can – AND SHOULD! – have another life. Your company can save 40-60% or more of the cost of a new, smaller insert if you take advantage of downsizing.

When you send us your dull inserts, we grind them to the new smaller standard size or a special request size.

As you specify, we will:

- Grind down one standard size or several

- Grind chip breakers back into the insert

- Complete new edge prep

- Recoat with original or superior coating for your application

Our precision process removes all stock without heat, thermal cracking or chipping. Custom honing in our plant provides tool life that often exceeds that of the original insert. Your inserts are carefully packaged and shipped promptly to you. We downsize squares, triangles, rounds, hexagons, pentagons, 80 degree diamonds, 55 degree diamonds, grooving tools and many more. Visit ‘Downsizing Inserts’ page

Regrinding

You know the cost of indexable carbide inserts and you know they are ever-increasing!

Because the charge for regrinding is only a fraction of the cost of a new insert, it is not only economical for you to have your inserts reground – you’ll surely agree that it’s necessary. For example, a $10.00 insert might cost only $2.00 to sharpen and $2.50 to downsize, depending on the quantities involved. Also, many of our reground inserts last LONGER than the original due to our expertise in carbide grinding, edge prep and superior coatings.

It’s easy to use our service:

- You send us your scrap carbide and tell us your needs. Sometimes we can even arrange to pick these up at your facilities.

- We inventory the material received and formally quote firm prices for the grinding/coating of each item.

- You give us formal approval and instructions to proceed.

- We work on your order and return your high quality reground inserts in approximately two to five weeks. (faster turnaround is possible)

Our Business is Run by Perfectionists

That’s why we can guarantee our work 100 percent. You can be assured that your order will receive individual attention, whether it’s large or small. We welcome the opportunity to show you what makes us the best source for your insert work.

Spade Drills & Replaceable Drills Tips

New Spade Drills

We manufacture high quality spade drills of carbide and T16 (super cobalt) that fit today’s standard holders. Uncoated or coated (TiN, TiCN, TiAlN…many other coatings available as well) spade drills are available. We can manufacture standard or special sizes and geometries.

Sharpening Spade Drills and Replaceable Drill Tips

Don’t pay full price for another spade drill when you can resharpen and recoat it for much less! Sharpening and re-coating of spade drills and replaceable drill tips is available to reduce your costs. Don’t pay full price for another spade drill or replaceable drill tip when you can resharpen and recoat it for much less! All grinding is done on our state-of-the-art 5 axis CNC grinding machines.

Visit ‘Sharpening Replaceable Drill Tips’ page

Tooling & Tooling Services

New Tooling:

- Drills

- End Mills

- Taps

- Reamers

- Brazed Tools

- Tool Holders (both standards and specials)

- Grinding Wheels (PCD and CBN)

- Diamond Dressers

- and much more

Tooling Services:

- Coating (TiN, TiCN, TiAlN, AlTiN, ZrN and many more).

- Repair of Tool Holders and Brazed tooling.

- Regrinding of all round tooling (drills, end mills, reamers, replaceable heads, and all others).

- Retip and relap PCD/CBN inserts

- and much more.

Visit ‘Tooling & Tooling Services’ page

Full Insert Grinding Service

Sorting

We will sort your used carbide inserts – by style and grade – and provide you with an inventory and pricing for downsizing and/or sharpening. THERE IS NO CHARGE FOR THIS SERVICE!!!

Determining Grinding Specifications

While we work with standard specifications, we will consult closely with you to determine the lowest cost and optimum specification for your application. We present any alternative possibilities and will provide samples.

Coating

We can apply or re-apply a wide range of coatings. Our experienced staff will work with you to decide the best coating for your application.

Recycling

We accept any coated or non-coated carbide items, including all types of inserts, mills, drills, taps, reamers, etc.

Visit ‘Full Insert Service & Recycling’ page

Sign Cutting Blades

Performance Carbide manufactures vinyl cutters, plotter blades/knives, slitting blades, trimming blades, cut-off knives and more.

Our blades are custom ground to fit Gerber, Ioline, Roland, Mimaki, Allen Datagraph, Anagraph, Mutoh, Summagraphics and many more!

Our blades provide:

- Superior, solid carbide.

- 100% guaranteed satisfaction on new and sharpened blades

- New blades, always made from new material

- Special blades to your specification and drawings

- Sharpening service